Commercial kitchens push equipment to the limit every single day. A failed seal stops service immediately and costs you money. You need to know exactly when your silicone parts will fail under heat.

Most standard food-grade silicone1 parts operate safely between 180°C and 250°C (356°F - 482°F). High-quality platinum-cured silicone2 with fiberglass reinforcement can withstand up to 260°C continuous use, while specialized high-heat formulations can endure short bursts up to 300°C without structural failure.

I have seen many designers struggle with this specific material limit. You must understand the nuances of heat resistance to design reliable kitchen equipment.

Does silicone really melt like other plastics?

Many engineers fear their seals will turn into liquid plastic inside a hot oven. This fear comes from a misunderstanding of how silicone differs structurally from standard thermoplastics.

Silicone does not melt. Unlike thermoplastics that become liquid when heated, silicone is a thermoset elastomer. Extreme heat causes it to dry out, crack, and eventually turn into brittle ash, but it will never melt into a puddle.

Understanding the Material Structure

I spent years in the LED and lithium battery industries before I started Pandasoft. In those fields, material failure usually meant a fire or a melted component. Silicone is different. It is unique because of its chemical backbone. Most plastics use a carbon-to-carbon backbone. Silicone uses a silicon-to-oxygen backbone. This bond is much stronger. It requires more energy to break.

When you heat a standard plastic like Polyethylene, the chains slide apart. The solid becomes a liquid. Silicone is "cured" or cross-linked. The molecule chains are tied together permanently. Heat cannot separate them to form a liquid.

What Actually Happens at High Heat

If you expose a silicone gasket to temperatures above 300°C (572°F), it will not drip. It will undergo "calcification." The organic side groups on the polymer chain burn off. Silica is left behind. The part becomes white and powdery. It loses all mechanical strength.

I often explain this to my clients using a simple comparison table. This helps them visualize the failure mode.

| Feature | Thermoplastics (e.g., PP, PE) | LSR / Silicone |

|---|---|---|

| Response to Heat | Softens, then melts into liquid | Hardens, then turns to ash |

| Reversibility | Can be melted and reshaped | Permanent shape once cured |

| Failure Mode | Loss of shape, dripping | Cracking, powdering, snapping |

| Chemical Bond | Weak intermolecular forces | Strong covalent cross-links |

The Importance of the Base Material

Standard silicone uses a simple mesh structure. It handles about 180°C. For higher performance, we use specific additives. We also change the reinforcement. A fiberglass cloth base drastically improves heat resistance. This allows the part to hold its shape up to 260°C. You must choose the right base material during the design phase. A wrong choice here leads to early failure in the field.

What are the specific signs of silicone degradation3 caused by high temperatures?

You might not see damage immediately during a standard inspection. Heat damage is often invisible until the part fails completely during a busy dinner service.

The first signs of thermal failure are hardening and a loss of elastic memory. The material becomes stiff. Later, you will see discoloration (usually darkening or yellowing) and surface cracking. If you bend it and it snaps, the silicone is heat-damaged.

Hardening and Loss of Elasticity

I always tell my clients to touch their parts. Visual inspection is not enough. The most critical property of LSR is its elasticity. This allows it to seal gaps. Heat attacks this property first. The scientific term is "embrittlement." The rubbery nature disappears. The part starts to feel like a hard piece of wood or hard plastic.

If your oven seal feels hard, it is failing. It might still look fine. But a hard seal cannot compress. Heat escapes the oven. Energy costs go up. Cooking becomes uneven.

Compression Set

This is a major issue in my experience with mold design. "Compression set" means the material stays flat after you squish it. It does not bounce back. High heat accelerates this.

- New Silicone: Bounces back to original shape immediately.

- Heat-Damaged Silicone: Stays flat.

If a door gasket stays flat, the door does not seal. Steam and heat leak out. This damages the control electronics usually located above the oven door.

Discoloration and Surface Changes

You can look for color shifts. Translucent silicone often turns yellow or brown. Colored silicone might darken. This is oxidation happening faster due to heat.

I have also seen "blooming." This looks like a white powder on the surface. It happens when low-quality filler materials migrate to the surface. This is common in cheap silicone. High-quality Platinum-cured silicone resists this better.

The "Snap" Test

I use a very simple test in my workshop. I take the old part. I bend it in half.

- Good Silicone: It bends. No cracks appear.

- Bad Silicone: It snaps into two pieces. Or, you see many small cracks appear at the fold.

This indicates the polymer chains are broken. The part is trash. You must replace it immediately. A snapping gasket can fall into food. This is a serious safety risk.

Besides temperature, what other factors affect silicone durability in a kitchen environment?

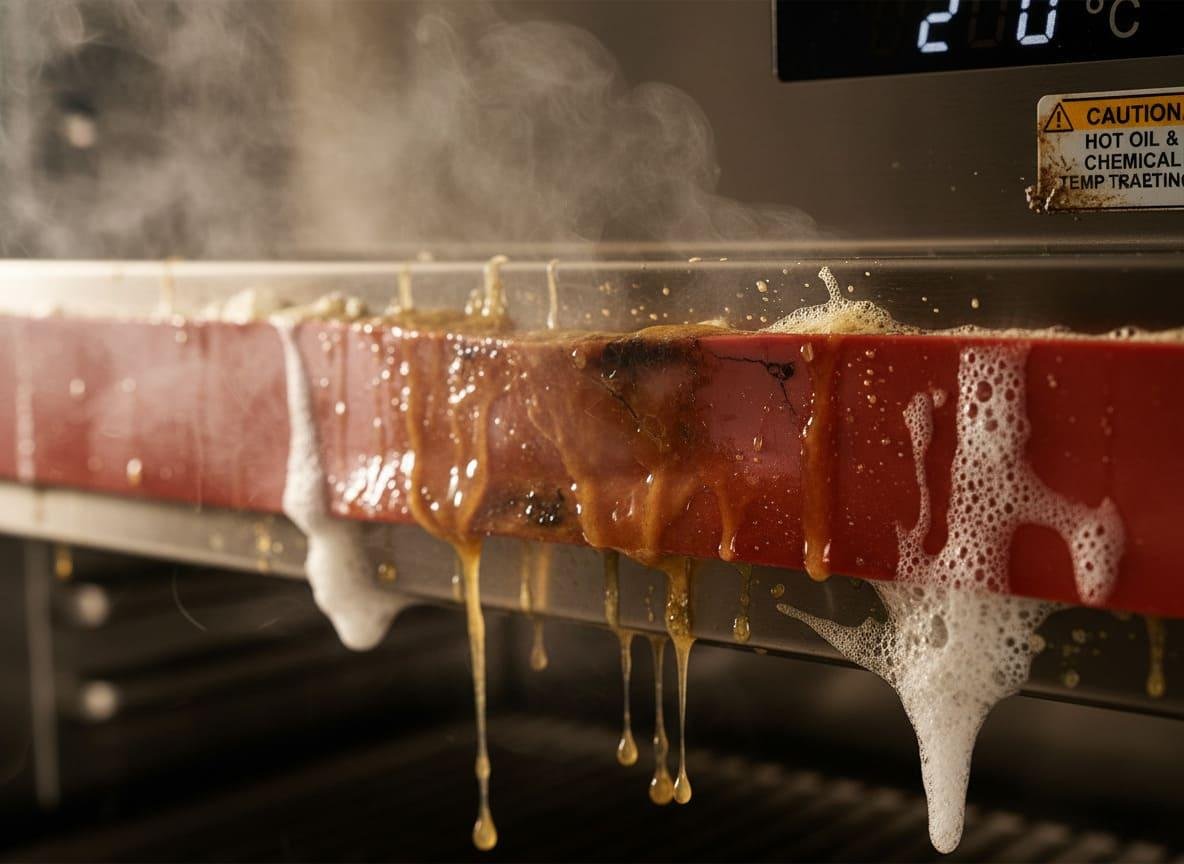

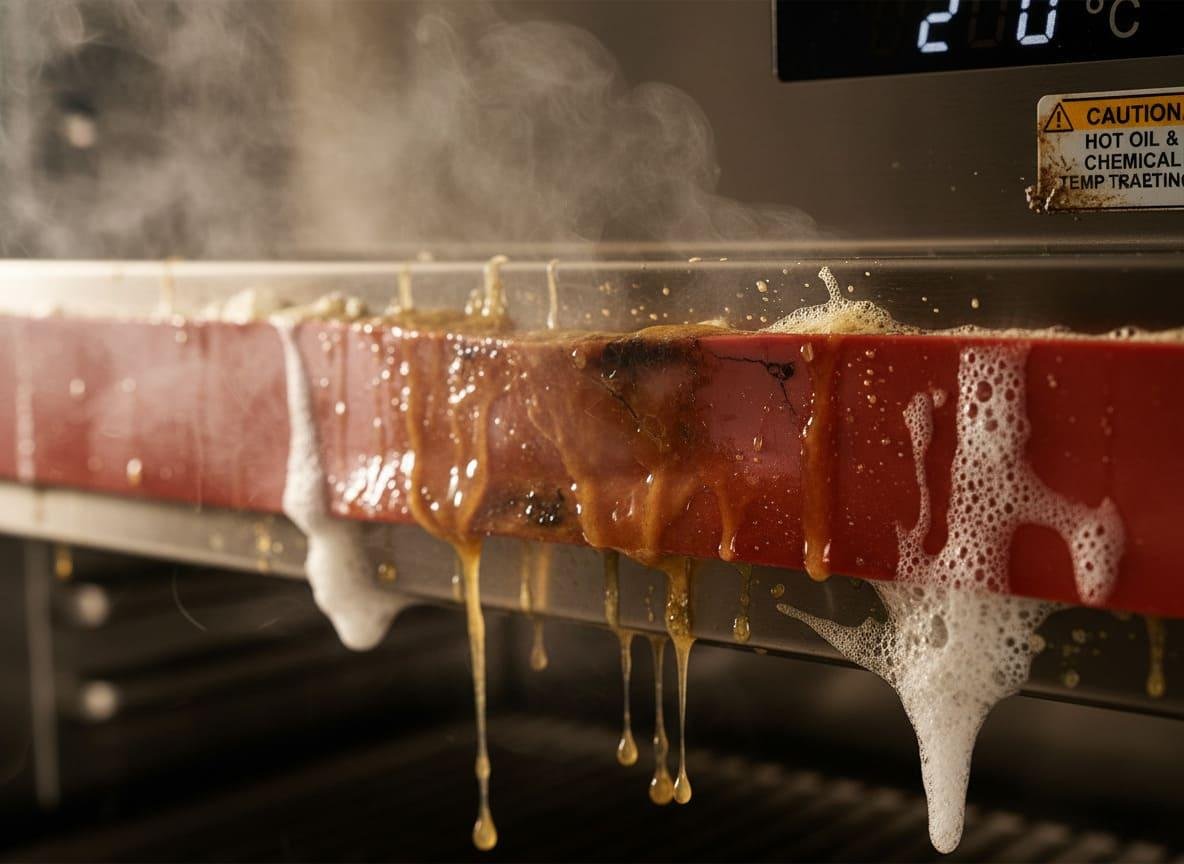

Heat is rarely the only enemy in a commercial kitchen. Chemicals and fats attack your seals at the same time as the oven heat.

Grease, acidic cleaners, and high-pressure steam significantly reduce silicone's thermal resistance. Animal fats can cause swelling, while strong alkalis degrade the polymer chain. A seal rated for 250°C in dry air may fail at 200°C when exposed to hot oil and aggressive detergents.

The Multiplier Effect

You cannot look at temperature data sheets in isolation. Those tests happen in dry, clean labs. Commercial kitchens are wet, greasy, and chemically aggressive.

I worked on a project for a deep fryer manufacturer. They used a seal rated for 250°C. The oil temperature was only 190°C. The seal failed in three weeks. Why? The hot oil permeated the silicone. It caused the material to swell. The swollen material became weak. The mechanical pressure of the clamp then cut through the soft silicone.

Common Kitchen Aggressors

You need to account for these three main factors:

-

Animal Fats and Oils: Silicone is chemically similar to some oils. It can absorb them. This causes swelling. A swollen seal changes dimensions. It might pop out of its groove. Once swollen, the heat resistance drops drastically.

-

Steam (Hydrolysis): Water is usually harmless. High-pressure steam is different. At high temperatures, water vapor acts like an acid. It attacks the silicone backbone. This is called hydrolysis. Standard silicone breaks down quickly in steam. You need special "steam-resistant" grades for combi-ovens.

-

Cleaning Chemicals: Kitchen staff use strong degreasers. These are often highly alkaline (high pH). If the staff does not rinse the seal perfectly, the chemical sits on the rubber. When the oven heats up, the chemical reaction speeds up. It eats the surface of the silicone.

Impact on Temperature Ratings

I created this guide based on my observations of returned parts. It shows how the environment lowers the safe operating limit.

| Environment | Standard Safe Limit | Risk Factor |

|---|---|---|

| Dry Heat (Baking) | 230°C - 250°C | Low. Oxidation is the main issue. |

| Steam (Combi-Oven) | 150°C - 200°C | High. Hydrolysis breaks down the material. |

| Hot Oil (Frying) | 180°C - 200°C | High. Swelling and mechanical tearing. |

| Chemical Residue | < 180°C | Extreme. Surface erosion and cracking. |

You must design for the worst-case scenario. If your machine uses steam, do not trust the dry heat rating.

How to determine if silicone parts in kitchen equipment need replacement?

Predicting failure is better than reacting to it. You need a schedule to change parts before they ruin a batch of food or damage the machine.

Establish a routine based on exposure. Replace parts in direct contact with heating elements every 6 months. Replace general high-heat seals annually. Immediate replacement is necessary if the Shore A hardness increases significantly or if the part takes a permanent set and no longer seals.

The "Dry Burn" Danger

I have investigated accidents involving "dry burns." This happens when a pot boils dry. The temperature shoots past 300°C in seconds. The silicone component touches this superheated metal.

In these cases, the silicone fails instantly. I have seen thermal mats catch fire. I have seen heat-conducting plates explode because the silicone buffer turned to powder. You cannot wait for a schedule here. If a dry burn event occurs, you must change every silicone part near the heat source immediately.

Recommended Replacement Schedule

Based on industry best practices and my experience with Platinum-cured products, I recommend this timeline:

- 6-Month Cycle: Parts that touch heating elements. Parts in steam generators. Gaskets in deep fryers.

- 12-Month Cycle: Door gaskets on ovens. Vibration dampeners inside the machine casing.

- 24-Month Cycle: Cold section seals. Control panel buttons.

Why Platinum Curing Matters Here

I always advise my clients to specify Platinum-cured silicone for kitchen use. Standard silicone uses Peroxide curing. Peroxide leaves byproducts. These byproducts smell bad when heated. They can also yellow quickly.

Platinum curing is cleaner. It is stronger. It handles repeated heating cycles better. It costs more, but it lasts longer. A Peroxide seal might need changing every 3 months in a heavy-use kitchen. A Platinum seal lasts a year. The maintenance labor savings pay for the material difference.

Establishing a Check Protocol

You should instruct the end-users (the kitchen staff) on how to check.

- The Wipe Test: When cleaning, does the cloth come away black? That is degrading rubber.

- The Pinch Test: Pinch the seal. Does it rebound?

- The Smell Test: Does the oven smell like burning rubber?

If any answer is "yes," send a technician. Do not wait. A leaking seal can damage the expensive electronics in modern smart ovens. A $10 seal protects a $500 circuit board.

Conclusion

Safe operating temperature is not just a number on a datasheet. While high-quality LSR withstands 250°C, chemical attacks and steam reduce this limit. You must choose platinum-cured, fiberglass-reinforced silicone for the best durability. Inspect high-heat parts every six months to prevent costly equipment failure.

Explore the properties and uses of food-grade silicone to understand its safety in kitchen equipment. ↩

Learn why platinum-cured silicone is preferred for kitchen applications due to its durability and safety. ↩

Understand the factors leading to silicone degradation to ensure better maintenance of kitchen equipment. ↩