How to Select the Right Food-Grade vs. Industrial-Grade Silicone Based on Heat Resistance Needs?

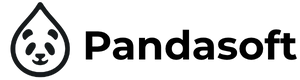

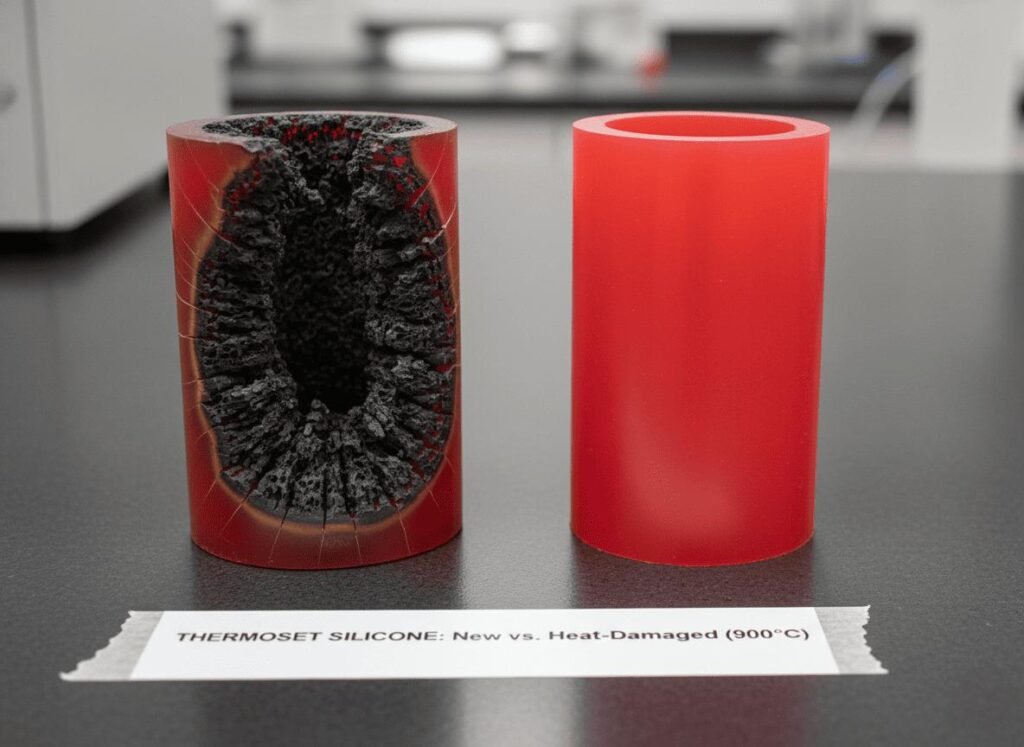

Choosing the wrong silicone for a high-heat application can cause product failure or safety issues. This mistake can be costly, leading to recalls and damaging your brand's reputation. Food-grade silicone is mandatory for food contact and typically handles temperatures from -40°C to 250°C. Industrial-grade is for non-food applications with a base heat resistance up to […]

READ MORE →